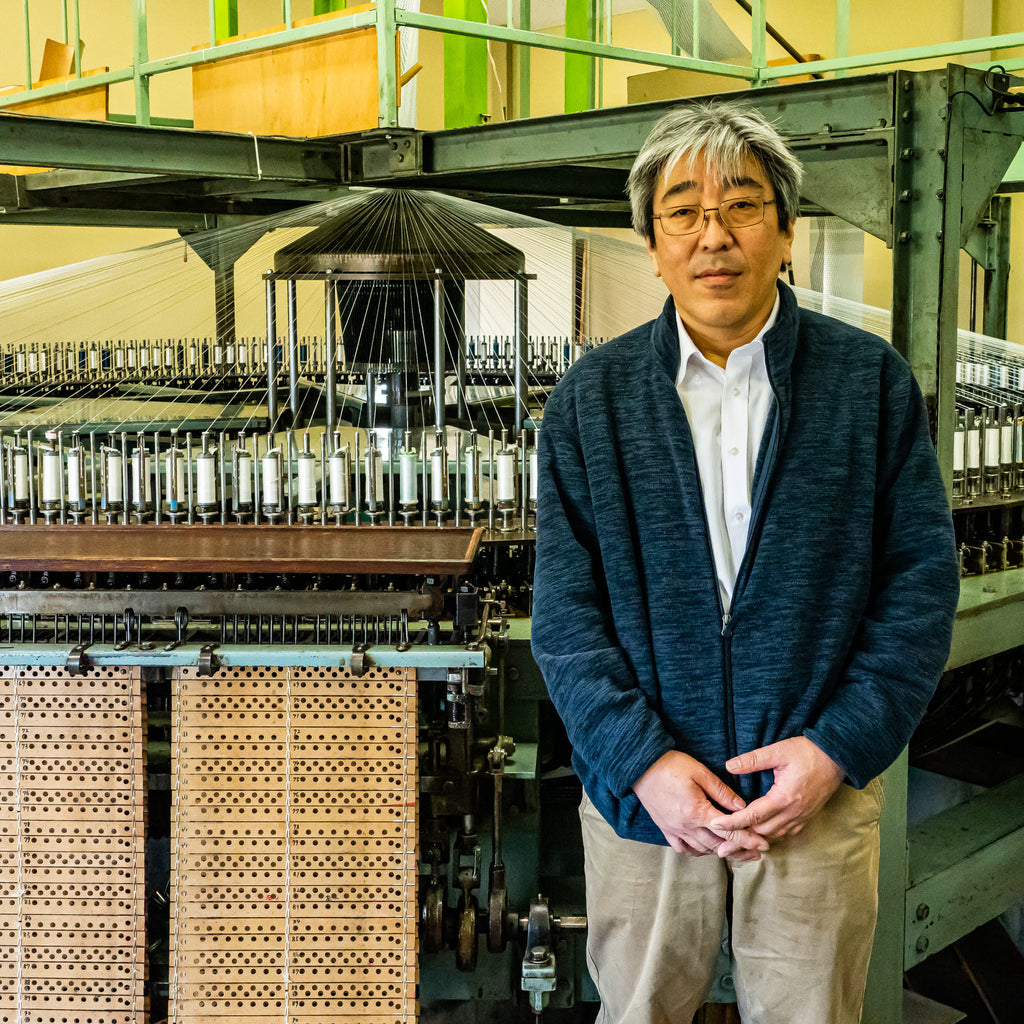

MUROKADO Koichiro

Introduction of Artist

Founded in 1949, the head office of Saiko Ltd. is located 5 minutes northwest by car from Kinkakuji Temple in Kyoto.

The "Sanjiku Kumiori" (triaxial weaving) manufactured by Saiko is the result of a fusion of the "Kyo-kumihimo" technique, which is said to have originated in Kyoto in the 700s AD, and the Italian torsion lace technique. This technique is prized as braided cords for storing sutras and as ornaments for formal attire of nobilities during the Nara period (700s). These items are still carefully preserved in the Shoso-in Repository, a gallery in Horyuji Temple, and Itsukushima Shrine on the island of Aki-no-Miyajima.

The circular loom used to weave triaxial weaving is a huge loom that is approximately 5 meters in diameter and 5 meters high. While ordinary textiles are woven by applying tension of up to approximately 10 kg from the vertical direction only, triaxial weaving is made on circular looms, which applies tension of approximately 200 kg from 360 degrees in all directions evenly while assembling. According to Murokado, this creates elasticity and makes it difficult to loosen as an obi fabric.

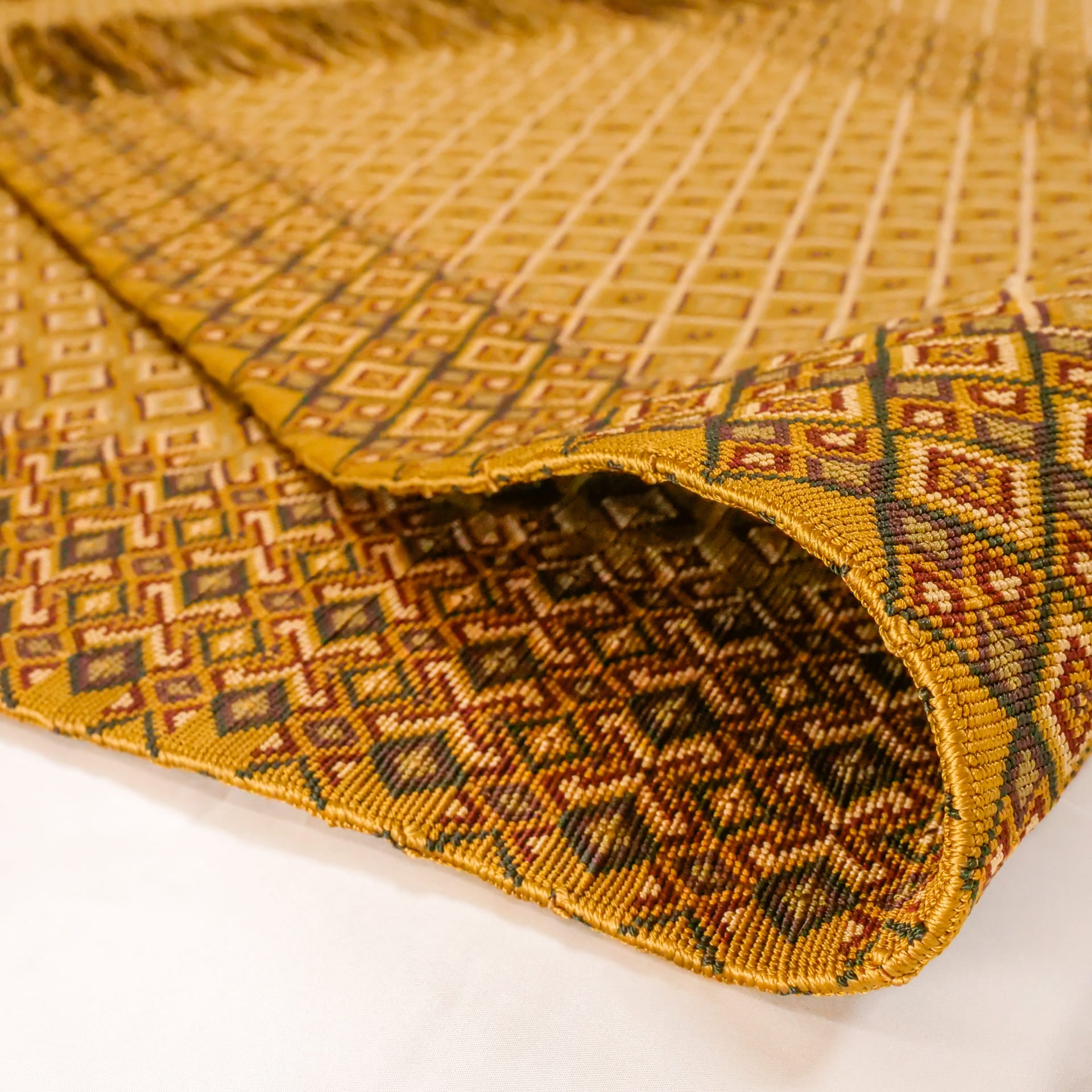

The fabric is woven using a complex technique in which warps from two diagonal directions cross at an angle of 45 degrees to the straight warp threads.

The diagonal structure prevents loosening and wrinkling, and the complex interlacing of the threads creates refraction of light, giving it a unique luster. Another feature is the use of a variety of colored yarns to create subtle gradations.

In the production process, preparation takes more time than weaving. 10 threads of the same length are wound on each of 480 bobbins on a loom, and if even one of them gets loose, the whole work is ruined, so hundreds of meters are wound while paying the utmost attention. This process takes three weeks. The threads are made of 100% pure domestic silk and set on the loom, which is then woven in one day by four people.

The loom is the most difficult to manage by hand due to the condition of the silk threads, which change with the weather. Because diagonal weaving involves a lot of friction when the threads are moved, especially in the winter, it is necessary to be careful of static electricity. So Kameoka, famous for having the most fog in Kyoto, was chosen as the production site, and weaving is carried out in a humid environment.

The large circular loom, which produces the triaxial weaving, was developed about 50 years ago by our predecessors in Nishijin, Kyoto, with the aim of restoring the braided obi from the Shoso-in Repository to its current width of about 30 cm or more. Six large circular looms were initially manufactured, but only two are currently working and both are owned by Saiko. The large circular loom is a valuable historical heritage that can attest to the development of the textile industry in Japan.

Saiko is the only company that procuces the triaxial weaving on the large circular looms in the world. Because of this, when a problem arises, the company is unable to procure the necessary parts and needs to deal with it in-house. Murokado says "We must maintain this technology at all costs and pass it on to future generations. In order to preserve our historical legacy for future generations, triaxial weaving must seek new collaborations with various products, not just kimonos."

Message

With the motto of "one and only manufacturing," we work together with eight craftsmen to create products. We have succeeded in establishing a original weaving style by handling various products such as "Sanjku Kumiori" weaving, "Nishijin omeshi" cloths, "waso kireji" cloths, "Karao Dantsu" rug, and "Ori-kinsai" cloths, and are now focusing on training younger generations of workers.

We study every day to pass on the skills we have cultivated over the years to future generations. Our fabrics, /which are/ woven with my own touch, are highly rated for their uniqueness and diversity. Please enjoy the unique texture of our silk threads.

Works

Profile

-

Artist name

MUROKADO Koichiro

-

Company name

Saiko Co., Ltd.

-

Activity area

Nishijin, Kyoto

-

Biography

- 2005

- Granted the Encouragement Award for Traditional Industries

- 2013

- Registered the trademark for "Sanjiku Kumiori" which is woven on the proprietary "large circular loom".

- 2019

- Exhibited at the 1st Kyoto International Gift Show Appeared on KBS Kyoto's "Kyo bizX" Featured in Shogakukan's "Sarai" and Kyoto Chamber of Commerce and Industry's "Kyo Business Review"

- 2020

- Listed on the Kyoto Prefecture website as a "Model Company for Wisdom Management Practice" Certified as a traditional craftsman in the Nishijin textile weaving category by the Minister of Economy, Trade and Industry Granted Excellence Award, the Kyoto Small and Medium Business

- 2021

- Granted Excellence Award, the 1st Japan Wabunka Grand Prix